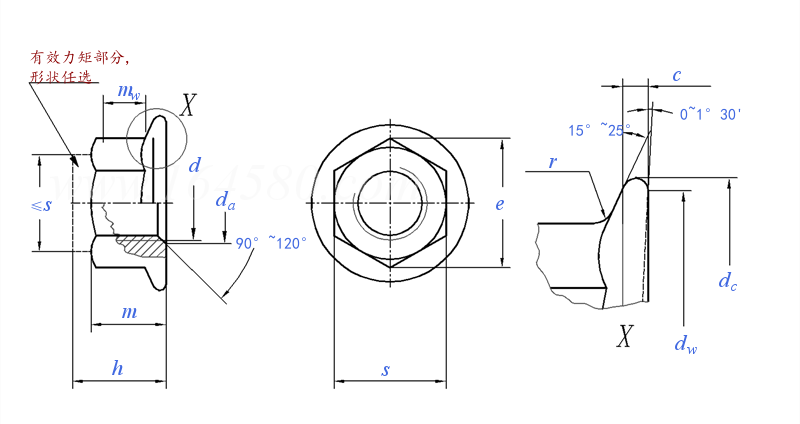

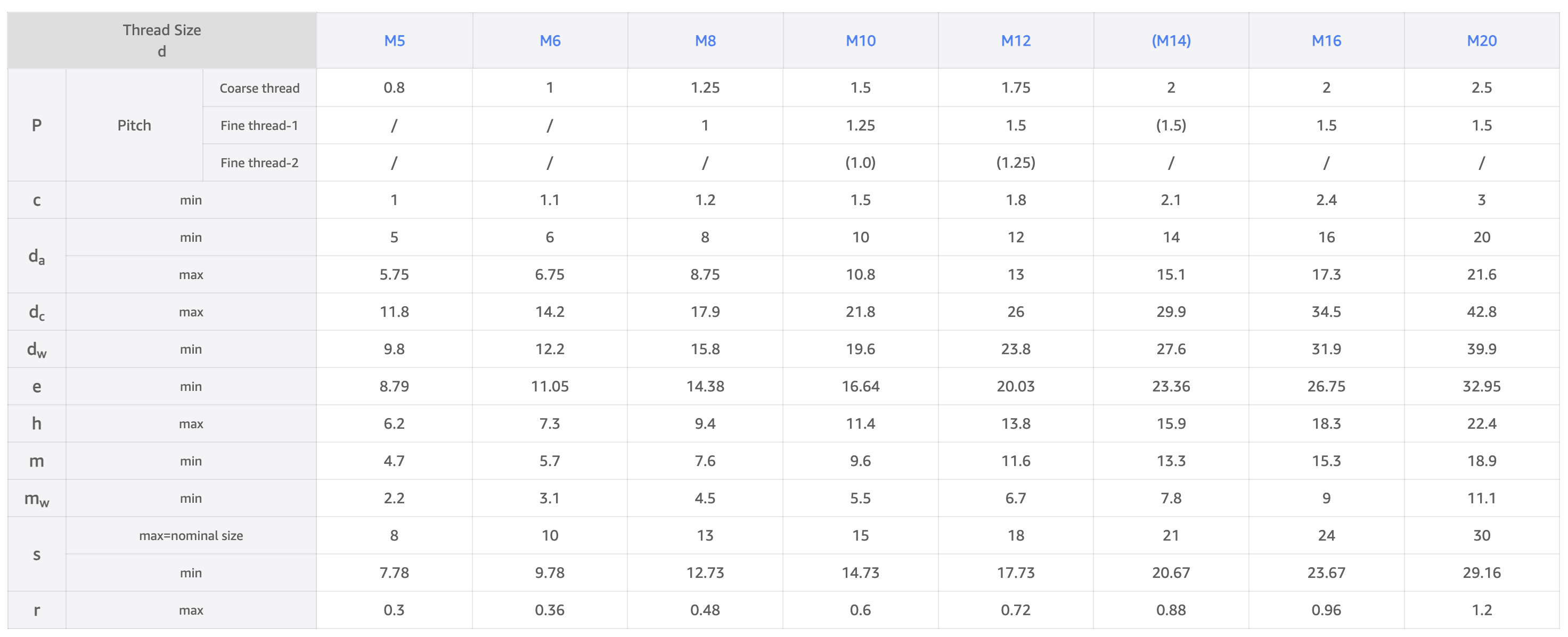

High strength hexagonal belt nut

Hexagonal belt nut is a special type of hexagonal nut characterized by a washer (meson) located below the hexagonal head of the nut.

The advantages of this nut include:

1. Enhance sealing: The gasket can increase the contact area between the nut and the connected part, improving the sealing effect.

2. Pressure dispersion: Helps to disperse the pressure generated during fastening and reduce damage to the surface of the connected parts.

3. Anti loosening: To some extent, it increases the anti loosening performance of the nut.

Hexagonal belt nuts are widely used in various fields such as mechanical assembly, automotive manufacturing, electronic equipment, etc., especially suitable for connection parts that require enhanced sealing, pressure dispersion, and improved anti loosening effect.

The installation and disassembly methods of high-strength hexagonal cap nuts are as follows:

Installation method:

1. Choose the appropriate tool: Based on the size of the nut, choose a matching wrench (such as an open-end wrench, a ring wrench, or a socket wrench).

2. Clean the threads: Ensure that the threads of the bolt and nut are clean, free of debris and rust.

3. Align thread: Carefully align the thread of the nut with the thread of the bolt.

4. Preliminary tightening: Use your hands to screw the nut onto the bolt a few times, and then use tools to preliminarily tighten it.

5. Tighten according to the specified torque: For important connections, use a torque wrench to tighten according to the specified torque value according to relevant standards and requirements.

Dismantling method:

1. Choose the appropriate tool: Similarly, select the appropriate wrench based on the size of the nut.

2. Loosen the nut: Use a wrench to turn the nut counterclockwise and gradually loosen it.

3. In case of rust or jamming: You can spray some loosening agent first and wait for a period of time before attempting to disassemble. If it is still difficult to disassemble, special methods such as heating and cutting may need to be used, but these methods should be used with caution to avoid damaging the components.

When installing and disassembling high-strength hexagonal cap nuts, safety should be taken into account to avoid excessive force that may cause injury or damage to the nuts and bolts.

When installing high-strength hexagonal cap nuts, the following measures can be taken to avoid thread damage:

1. Ensure thread cleanliness: Before installation, carefully clean the dust, debris, rust, or other foreign objects on the bolt and nut threads to prevent these impurities from entering the threads and causing damage.

2. Correct alignment of threads: Align the threads of the nut accurately with the threads of the bolt to avoid forced insertion causing thread misalignment and damage.

3. Moderate lubrication: Apply an appropriate amount of lubricant on the threads, such as butter, engine oil, or specialized thread lubricant, which can reduce friction between threads and lower the risk of damage.

4. Choose the appropriate tool: Use a wrench or socket tool that matches the size of the nut and has good quality. Avoid using worn or unsuitable tools to prevent uneven force on the nut and damage to the thread.

5. Uniform force application: When tightening the nut, apply force evenly and gradually, avoiding sudden or unilateral force, and ensuring that the nut is smoothly screwed into the bolt.

6. Control tightening force: Use a torque wrench to tighten according to the specified torque value, avoiding excessive tightening that may cause thread deformation or damage.