High strength T-bolt DIN 188, grade 8.8, tenon M10X35

Grade: 4.8, 8.8, 10.9, 12.9, Material: Q235, 35K, 45K, 40Cr, 20Mn Tib, 35Crmo, 42Crmo, Surface Treatment: Blackened, Electrogalvanized, Dacromet, Hot-dip Galvanized, Galvanized, etc!

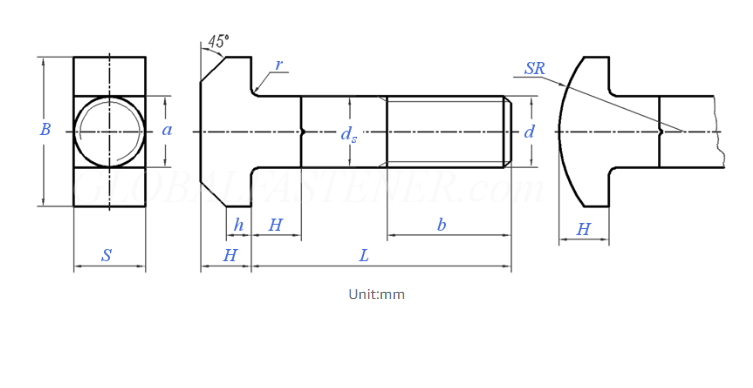

T-shaped bolt, from the appearance, has a T-shaped head. The T-bolt can be directly inserted into the aluminum groove, and it can automatically position and lock during installation. It is often used in conjunction with flange nuts and is a standard matching connector when installing corner pieces. It can be selected and used according to the width of the groove and different series of profiles. T-bolts belong to movable anchor bolts.

The characteristics of T-bolts include:

1. The unique structure ensures good stability and positioning during installation and use.

2. It is usually made of high-strength materials, which have high tensile and shear strength.

T-bolts have a wide range of uses:

1. Mechanical manufacturing industry: used for the assembly and fixation of equipment such as machine tools and molds.

2. In the field of architecture, it plays a role in connecting and fixing building structures such as curtain walls and steel structures.

3. Rail transit: used for fixing the track and installing connecting components.

4. Furniture manufacturing: Some furniture assemblies and structural connections use T-bolts.

5 Electronic devices: The internal structure of some electronic devices is fixed.

For example, in the installation of aluminum alloy doors and windows, T-bolts can firmly fix the frame of the door and window to the wall. In industrial automation equipment, T-bolts can ensure precise connections and stable operation between various components.

T-bolts of different materials and specifications are suitable for different scenarios and needs. For example, stainless steel T-bolts have good corrosion resistance and are commonly used in damp or corrosive environments; High strength alloy steel T-bolts are suitable for equipment and structures that require high load-bearing capacity.

Product standards

The national standards for T-bolts include:

GB/T 2165-1991 Machine Tool Fixture Parts and Components T-groove Quick Release Bolts (Obsolete) were adjusted to JB/T 8007.2-1995 and later replaced by JB/T 8007.2-1999 | Machine Tool Fixture Parts and Components T-groove Quick Release Bolts

GB/T 37-1988 T-groove bolts

There is also a mechanical standard: JB/T 1709-1991 T-bolts (obsolete), replaced by JB/T 1700-2008 valve components nuts, bolts, and plugs

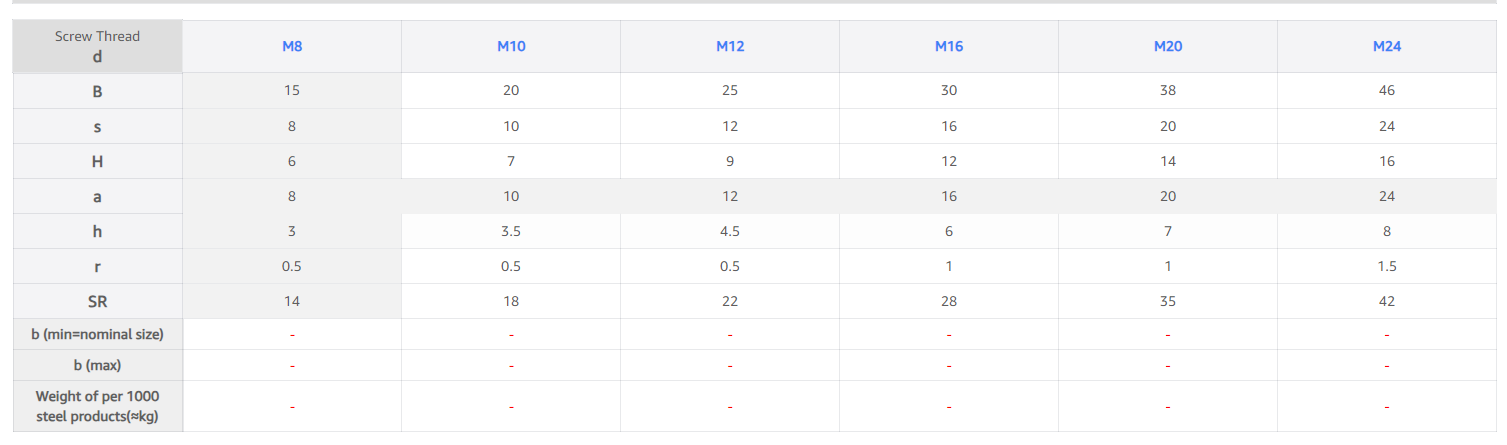

At present, commonly used are DIN186 T-shaped square neck bolts, national standard GB37, DIN188T-shaped double neck bolts, materials include carbon steel, stainless steel, alloy steel, etc., with specifications ranging from M8-M64. The domestically produced high-quality hardware with good quality control - Musheng, has formed a mature process.