Sell high hardness bolts for steel structure connection bolts

| use | Used for the connection between floor beams and reinforced concrete |

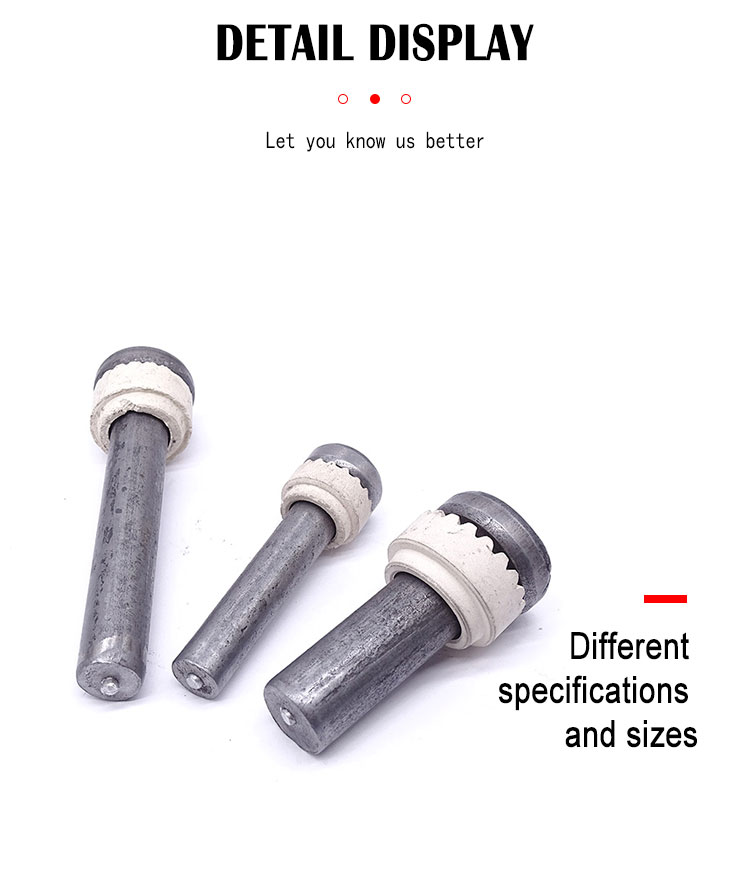

| shape | Long cylinder |

| material | carbon steel |

| trait | Strength |

| customizable | Support customization, OEM processing |

| Production process | Cold forging, hot forming, machining, heat treatment, galvanizing |

| technology | galvanize |

| Product size | 16*100mm |

| Package size | 50*80*10cm |

Welding nails are a type of fastener with high-strength and rigid connections.

The head of the welding nail is usually circular or nearly circular, with one or more annular ribs, used to enhance the bonding force with the welding base material. The shaft is a smooth cylindrical shape, usually made of low carbon steel or medium carbon steel.

Welding nails are commonly used in steel structure buildings to connect steel components such as steel beams and columns with concrete components. The installation method is usually to weld one end of the stud to the base metal through arc stud welding, and the other end is used to connect other components or provide support.

Welding nails have the advantages of convenient construction, reliable connection, and strong load-bearing capacity, and have been widely used in modern building structures.

The welding process of welding nails mainly includes the following steps:

1. Welding preparation

Choose appropriate welding nails and welding equipment.

Clean the welding area of impurities such as rust, oil stains, and moisture to ensure a clean welding surface.

Determine the welding position of the stud according to the design requirements and mark it.

2. Debugging of welding equipment

Set parameters for the arc stud welding machine, such as welding current, welding time, lifting height, etc. The selection of these parameters depends on factors such as the specifications of the weld stud, the material and thickness of the base material.

3. Welding

Place one end of the welding nail at the welding site and press it tightly with a welding gun.

Start the welding equipment, and under the action of the welding gun, the welding nail is instantly lifted and ignited, forming a welding arc within the specified time.

The welding arc causes the end of the weld stud and the base metal to partially melt, and the weld stud is inserted into the base metal under pressure, forming a welded joint.

4. Welding quality inspection

• Appearance inspection: Check whether the appearance of the weld seam is uniform and full, and whether there are defects such as porosity, slag inclusion, and undercutting.

Bending test: For sampled welding nails, a bending test is conducted to verify the strength of the welded joint.

It should be noted that the welding process of welding nails needs to be operated by professionally trained and qualified welders to ensure welding quality and construction safety.